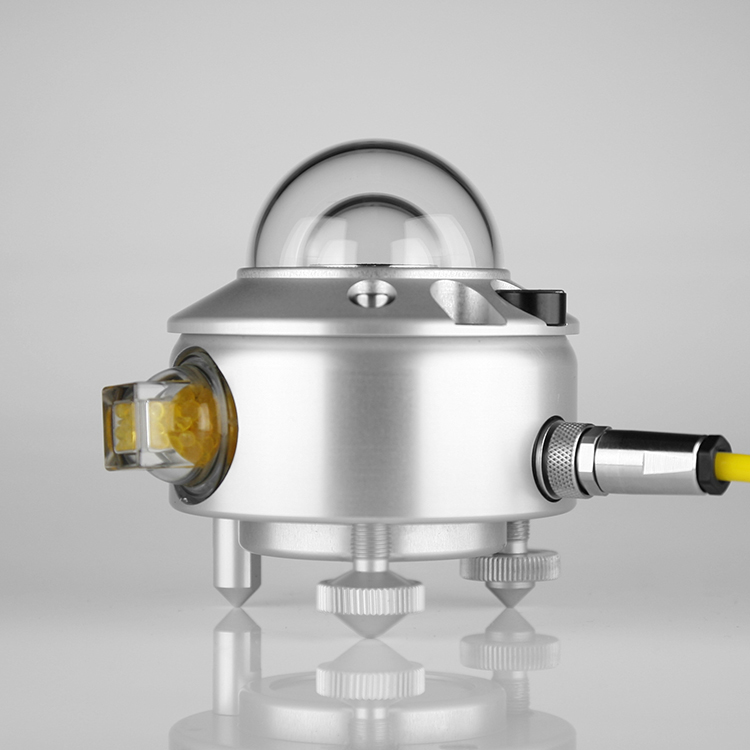

Installing your Class A pyranometer is the first step to obtain accurate solar irradiance data, pyranometer maintenance is the next. Whether it is extreme heat, frost, dew, snow, or wildlife, every day is a battle for your pyranometer. As a pyranometer’s thermopile sensor relies on receiving all sunlight for quality data, regular maintenance is key to obtain this.

Natural causes effecting measurements.

When setting up pyranometers, light obstructions account for a large proportion of positioning. Consequently, sensors are placed away from obstructions such as trees, fences, and structures. However, accounting for weather-induced obstructions is not so simple. Installing a ventilator will reduce the effects of dust, dew, frost, and snow. However, one does not negate the need for regular maintenance.

DUST

Dust and sand are always an issue for pyranometers. Even areas with no local dust or sand nearby receive dust suspended in rainfall. Though a ventilator will minimise the build-up of dust it will not prevent it completely. As a result, dust build-up will reach a point that dramatically reduces received solar radiation. In susceptible areas, an extreme weather event can cause this overnight.

IEC 61724-1 Class A solar monitoring requires that pyranometer domes are cleaned at least once per week.

DEW

The formation of dew requires cool mornings which reduce the temperature of a pyranometer’s dome. When cool enough and with moisture in the air condensation forms. As this normally occurs during the morning the measurements for the first couple of hours maybe be much lower than normal, especially as irradiance is lower in the morning too. Fitting a heated ventilator to a pyranometer virtually eliminates this.

WILDLIFE

Swooping birds and venomous spiders not only cause problems for humans in Australia, they can also reduce the accuracy of your pyranometer’s measurements. It is not uncommon for spiders to take residence under the sun shield or inside the ventilator. When a spider spins a web it can obscure the dome and limit received light. Bird droppings also have the same effect. As a result, in both cases, the data output will read lower than the true value. Some insects also use any warmth generated by heaters in the evenings or early mornings, this will reduce the light received when they settle.

SNOW AND FROST

Thick layers of frost and snow will reduce the light received until melted. Again, a ventilator with heater will mitigate this providing the snow is not too deep or frost is not too thick.

Pyranometer Maintenance tips

Pyranometer maintenance is continuous process, weekly, monthly and yearly checks need to be performed.

Weekly

- Clean pyranometer dome – Critical for Class A pyranometer which must conform to IEC 61724-1. Use de-ionised water and a soft lint cloth.

Monthly

- Check fixings and connectors – Connectors should be finger tight and not loose.

- Leveling and alignment – Pyranometer should be flat or on the correct POA.

- Sun shield fitting – The sun shield should be checked it is on securely. Therefore ensuring it does not obscure the dome.

- Check for spider webs – Removing any webs will ensure no web obscure the dome. Found a spider? Take care and good luck!!

- Inspect ventilation unit (if present) – Ensure there is airflow over the dome of the unit.

- Desiccant cartridge – Check pyranometers with external desiccant cartridges’ saturation levels. Replace if required. Pyranometers with internal cartridges do not need to be inspected.

Annually

- Electrical signals – Ensure signals are clean and secure by wiring back to the datalogger or SCADA.

- Recalibration – Recalibrate pyranometers with a reference-grade pyranometer every 1 – 5 years, depending on the application. This has to be performed at the manufacturer’s facility.

- Grounding continuity – Ensure continuity is good. A qualified person should perform this.

- Fittings and mountings – Inspect for corrosion or anything which could cause the pyranometer to move position.

Should you have any questions or need further advice on pyranometer maintenance then please do not hesitate to contact us.