ESS Earth Sciences are frequently asked what is the difference between the SMP10 pyranometer and SMP11 pyranometer? We will save you some time so you don’t have to read all of this article; there is virtually no difference in terms of accuracy and sensitivity between the two versions. The acquired data will be the same. However, there is one big difference, if you are still interested please read on.

The similarities.

The similarities between the SMP10 and the SMP11 are best shown using numbers. Below you will see the performance specifications of the two versions of the pyranometer. Notice that the specification of the SMP10 and SMP11 are identical.

Skip this table if you want to get straight to the differences.

| SPECIFICATION | SMP10 | SMP11 |

| Classification to ISO 9060:1990 | Class A (Secondary Standard) | Class A (Secondary Standard) |

| Analogue output • V-version | 0 to 1V | 0 to 1V |

| Analogue output range* | -200 to 2000W/m | -200 to 2000W/m² |

| Analogue output • A-version | 4 to 20mA | 4 to 20mA |

| Analogue output range* | 0 to 1600W/m² | 0 to 1600W/m² |

| Serial output | RS-485 Modbus® | RS-485 Modbus® |

| Serial output range | -400 to 4000W/m² | -400 to 4000W/m² |

| Response time (63%) | < 0.7 s | < 0.7 s |

| Response time (95%) | < 2 s | < 2 s |

| Spectral range (20 % points) | 270 to 3000nm | 270 to 3000nm |

| Spectral range (50% points) | 285 to 2800nm | 285 to 2800nm |

| Zero offsets (unventilated) | ||

| (a) thermal radiation (at 200 W/m²) | < 7 W/m² | < 7 W/m² |

| (b) temperature change (5 K/h) | < 2 W/m² | < 2 W/m² |

| Non-stability (change/year) | < 0.5% | < 0.5% |

| Non-linearity (100 to 1000W/m²) | < 0.2% | < 0.2% |

| Directional response (up to 80 ° with 1000W/m² beam) | < 10 W/m² | < 10 W/m² |

| Temperature response | < 1% (-20°C to +50 °C) < 2% (-40 °C to +70 °C) | < 1% (-20°C to +50 °C) < 2% (-40 °C to +70 °C) |

| Spectral selectivity (350 to 1500nm) | < 1% | < 1% |

| Tilt response (0 ° to 90 ° at 1000W/m²) | < 0.2% | < 0.2% |

| Field of view | 180 ° | 180 ° |

| Accuracy of bubble level | < 0.1 ° | < 0.1 ° |

| Power consumption (at 12 VDC) | V-version: 55mW | V-version: 55mW |

| A-version: 100mW | A-version: 100mW | |

| Software, Windows™ | Smart Sensor Explorer Software, for configuration, test and data logging | Smart Sensor Explorer Software, for configuration, test and data logging |

| Supply voltage | 5 to 30VDC | 5 to 30VDC |

| Detector type | Thermopile | Thermopile |

| Operating and storage temperature range | -40 °C to +80 °C | -40 °C to +80 °C |

| Humidity range | 0 to 100% | 0 to 100% |

| MTBF (Mean Time Between Failures) ** | > 10 years | > 10 years |

| Ingress Protection (IP) rating | 67 | 67 |

| Onsite pyranometer uncertainty | Calculate with Suncertainty App | Calculate with Suncertainty App |

| Recommended applications | High performance for PV panel and thermal collector testing, solar energy research, solar prospecting, materials testing, advanced meteorology and climate networks | High performance for PV panel and thermal collector testing, solar energy research, solar prospecting, materials testing, advanced meteorology and climate networks |

SMP10 Pyranometer and SMP11 Pyranometer – The Differences

There is only one difference between the SMP10 pyranometer and SMP11 pyranometer, which is the location of the moisture-absorbing material (desiccant). In the SMP10, the desiccant is located and sealed within the body. Whereas, in the SMP11, the desiccant is in a drying cartridge screwed into the outside.

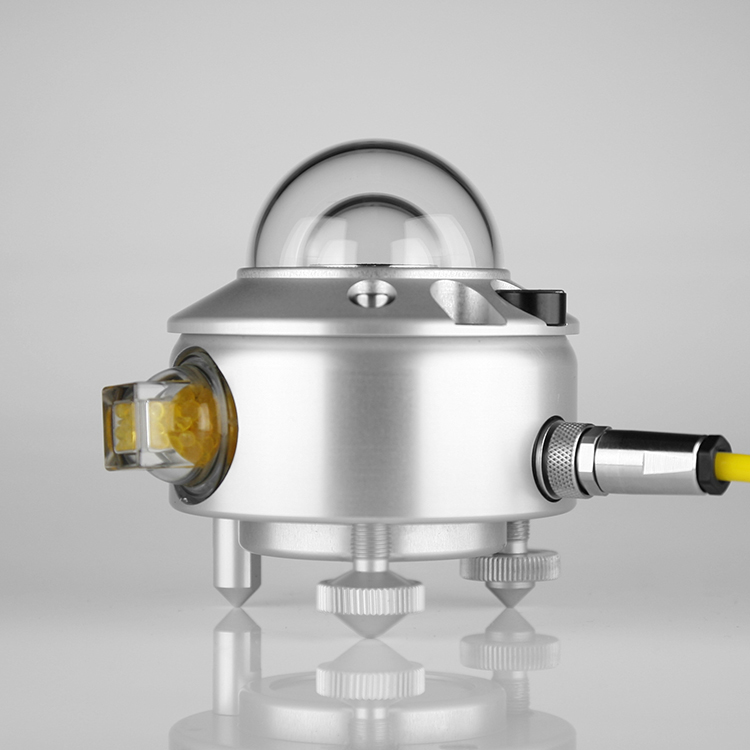

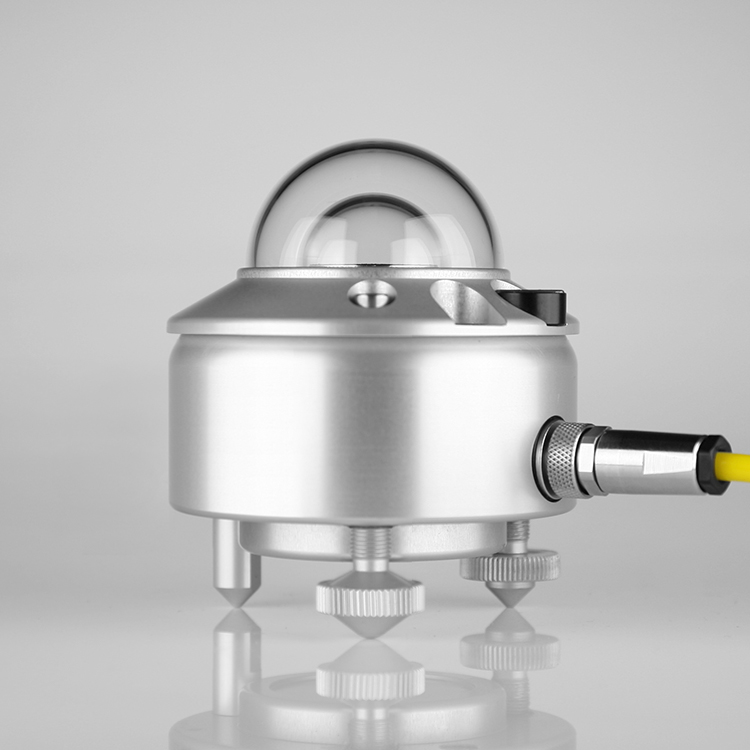

If you look at the photos below you will notice that the SMP11 (on the left) has a see-through cartridge protruding with yellow desiccant in. However, this is not on the SMP10. The same applies to the analogue only CMP10 CMP11 pyranometers from Kipp and Zonen.

As a result of the SMP10’s desiccant being held within the body of the pyranometer, there is a near-total elimination of ‘access’ points for moisture to ingress. Subsequently, the SMP10’s internal drying cartridge only requires changing after 10 years. As standard, it is changed every time it is sent to the manufacturer for re-calibration (should be performed every 1-5 years).

When to change cartridge

For the SMP11 it is crucial that the drying cartridge be inspected every month to check for decolouration of the desiccant which indicates it is reaching saturation from absorbing moisture. Though in less humid areas this can be extended to a longer period of time.

Stay up to date with all ESS Earth Sciences news and events by following us on LinkedIn