The Australian Standard for Blast Monitoring (AS2187.2-2006) provides guidelines for the type of equipment required to monitor ground vibration (peak particle velocity, or PPV) and airblast overpressure (sound pressure level, or SPL). Here we will help you understand the equipment that you need to use to perform compliance monitoring for blasting.

Monitoring for Potential Damage

Unoccupied structures of reinforced concrete or steel construction have ground vibration limits for cosmetic damage of 100mm/s. Other structures or architectural elements that include masonry, plaster, and plasterboard in their construction have frequency-based limits. For reinforced or framed structures, industrial and heavy commercial buildings, the ground vibration limit is 50mm/s at 4Hz and above. For unreinforced or light framed structures, residential or light commercial type buildings, the limit is 15mm/s at 4Hz. This increases to 20mm/s at 15Hz, and to 50mm/s at 40Hz and above.

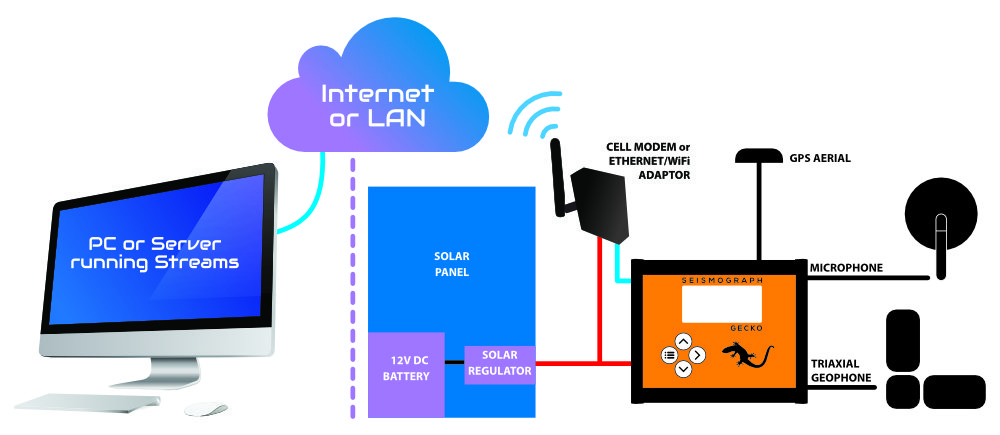

The basic tools for blast monitoring include:

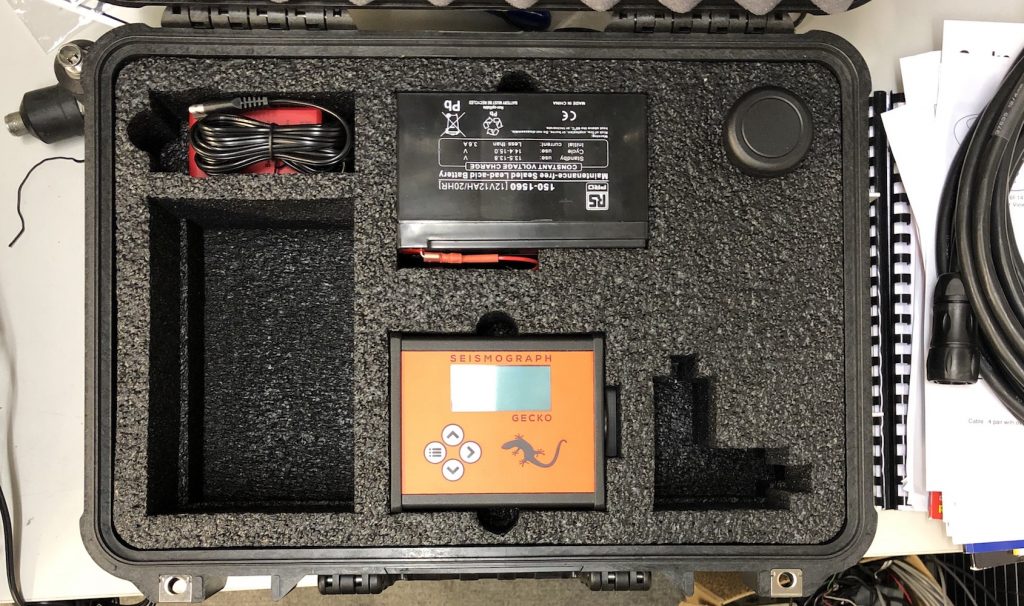

- Seismic Recorder (data logger)

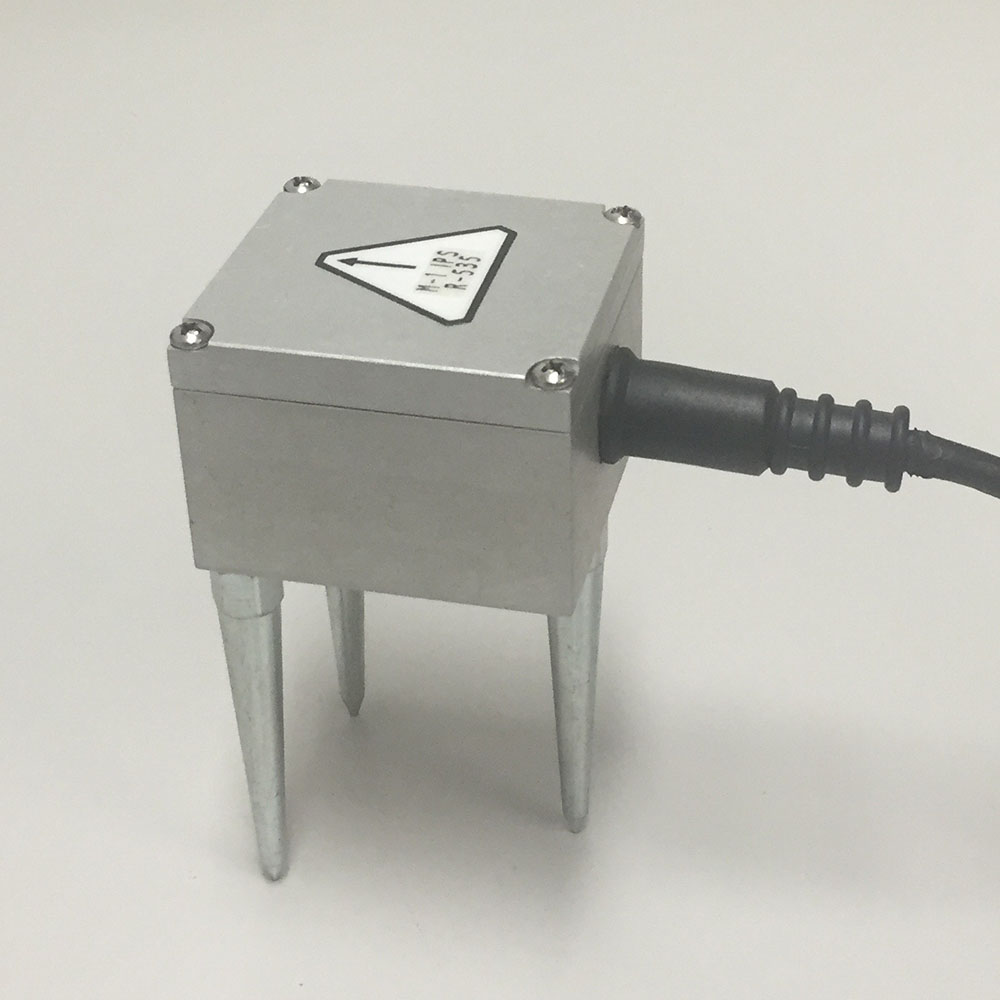

- Velocity Sensor (geophone)

- Air Pressure Sensor (microphone)

- Power (battery and charger)

The tools are simple enough to operate, however selection of technically suitable tools is a little more complicated. The 2006 update to the Australian Standard recommends certain technical requirements for ground vibration monitoring equipment.

Relevant Notes from the Standard

The frequency range of the measurement equipment shall be at least 2 Hz to 250 Hz (−3 dB roll off), with a tolerance of 10% over this frequency range

…however, this is qualified by also stating that:

The use of equipment with a frequency response range of 5 to 250 Hz, which was specified in AS 2187.2—1993, should be permitted in the vast majority of situations where this frequency range is adequate” which allows for more affordable instrumentation.

Similarly, the standard recommends for airblast overpressure that:

The frequency range of the measurement equipment shall be at least 2 Hz to 250 Hz (−3 dB roll off), with a tolerance of ±1 dBL over this frequency range

For both parameters the standard recommends that:

For a digital system, the recommended minimum sampling frequency is 500 Hz

Instrumentation Solution

The Gecko recording system uses earthquake observatory-grade low-noise high-resolution digitisation, but at traditional blast monitor costs. It can easily record continuous data at 500 samples per second (sps), and can even stream continuous data at this rate over a network connection. Four 24-bit input channels can accept signals from any type of sensor, perfectly suited to recording a 3D ground motion sensor and 1D microphone. With a standard storage capacity of 32GB, at 500sps the Gecko will store the last 120 days of continuous 4-channel data in a ring buffer. The Gecko can even store continuous data at 4000sps for around 2 weeks on the standard SD card which is user-upgradable, with cards of up to 1TB capacity readily available.

We have a range of low-cost 4.5Hz geophones or 2Hz geophones depending on your monitoring requirements, and 2Hz microphones, all of which meet the requirements of the standard. We also have low noise 2Hz geophones and microphones available for research applications.

ESS Blast monitoring packages.

ESS Earth Sciences has two standard packages for blast monitoring – permanent and portable. The permanent system is based around a low profile solar-powered instrument enclosure where the geophone can be placed outside or inside the enclosure. Similar enclosures have operated in the field by our SRC division for over 30 years. The portable system houses all of the recording components in a carry case. The case includes a small battery that offers several days of runtime. The sensors are connected to the carry case, which can also be left operating long term by using the included battery charger.

For further information about affordable and easy to use blast monitoring systems, please contact us.

Follow us on LinkedIn today to stay uptodate with our offers and news.